- Hakkımızda

- Ürünler

-

-

INDUSTRIAL SOLUTIONS

Visit our dedicated infrared solutions website for more information on industrial infrared ovens and services.

-

-

-

- Bilgi ve Destek

-

-

-

Latest Blog

K 2019 in review

They had an enjoyable week hosting many visitors to the stand from all over the world. Of course, they no ... Devamını oku...K 2019 in review

-

-

- Nereden Alabilirim?

- İletişim

- Ceramicx Isıtma Çözümleri

- Hesabım/ Giriş / kayıt

- Sepet

Tarihçe

Home Hakkımızda Tarihçe

Ceramicx 1992 senesinde Frank ve Gráinne Wilson tarafından kurulmuştur.

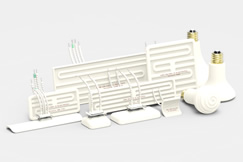

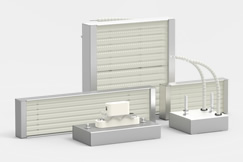

The company designs and manufactures ceramic infrared heating elements and complete turnkey infrared heating systems/ovens for industrial and commercial applications. Ceramicx’s products and systems are used in a wide range of applications such as packaging, automotive and aerospace amongst others in applications such as thermoforming, preforming, pressure forming, welding, non contact drying, spot heating and numerous other industrial processes.

Since its initial inception the company has gone from strength to strength establishing a policy of backward Integration (opposite to outsourcing) with respect to machinery and equipment and exporting 98% of the goods produced to 80+ countries. Primary markets include Germany, UK, USA, Russia, Turkey, India, and China.

In its initial years Ceramicx regularly achieved growth of over 30%, this slowed during the Celtic tiger and forced Ceramicx to consolidate and focus on cutting costs to remain internationally competitive. Ceramicx bided its time maintaining turnover levels until the collapse of the Celtic tiger and Ireland’s focus was firmly turned to manufacturing exports once again.

In the last 10 years Ceramicx has found itself on a trajectory of growth with average growth levels of 15% annually to the current year. The company has also founded an R&D strategy investing heavily in people and equipment to move Ceramicx towards becoming one-stop providers for solutions, components and equipment builds.

In 2017 Ceramicx reached a new turning point with the completion of a major building expansion project. New office space, larger machine/oven building space and clean room environments are all aiding future growth.

Bizimle iletişime geçin.

İnfrared ısıtma uzmanlarımız sorularınızı yanıtlamaktan memnun olacaklar.